Description

OGP SNAP VIDEO MEASUREMENT SYSTEMS

SNAP Large FOV Video Measurement Systems are compact measuring systems that integrate perfectly from the shop floor, to the lab, or as part of an automated work cell. Rugged construction and an open work envelope make SNAP easy to implement in virtually any manufacturing setting.

All SNAP systems feature large field of view optics, high resolution cameras, and lighting custom-designed to optimize the image, creating a complete optical system. Camera, optics, lighting, and platform are matched and tuned for optimum performance.

Measure-X software provides users with a simple, powerful interface for instant 2D measurement, virtual chart gaging, and profile analysis. Optional ZONE3 software combines Parallel Processing with intelligent routine Optimization resulting in faster programming and run times by measuring as many features as can be seen simultaneously.

OGP SNAP PDF Brochure

SNAP 100 offers simple walk-up and measure capability. Simply place the part on the worktable and press GO. SNAP 100 includes

Automation Speeds Throughput SnapShot identifies and measures features instantly without programming. Measured results are easily reported and exported.

Telecentric Optics

Ensure accurate measurements across the wide field of view with low distortion even when not perfectly focused. Zoom Anywhere technology instantly zooms the image anywhere in the wide field of view to measure small features instantly.

Simplicity and Value

With its small footprint, the robust SNAP 100 uses three light sources, and a high-density metrology camera to make it the best choice for accurate measurements in the lab and on the shop floor.

SNAP 100 PDF Brochure

Standard

Optional

Measuring Unit

Rigid, cast aluminum base; nickel plated worktable, with fixture holes, removable stage glass, 4 kg recommended max payload

Stage

Motorized, programmable 75 mm Z axis (focus)

Maximum Measuring Range (XY)

62 mm x 46 mm

Rotary Axis

Miniature Servo Rotary (MSR)

Optics

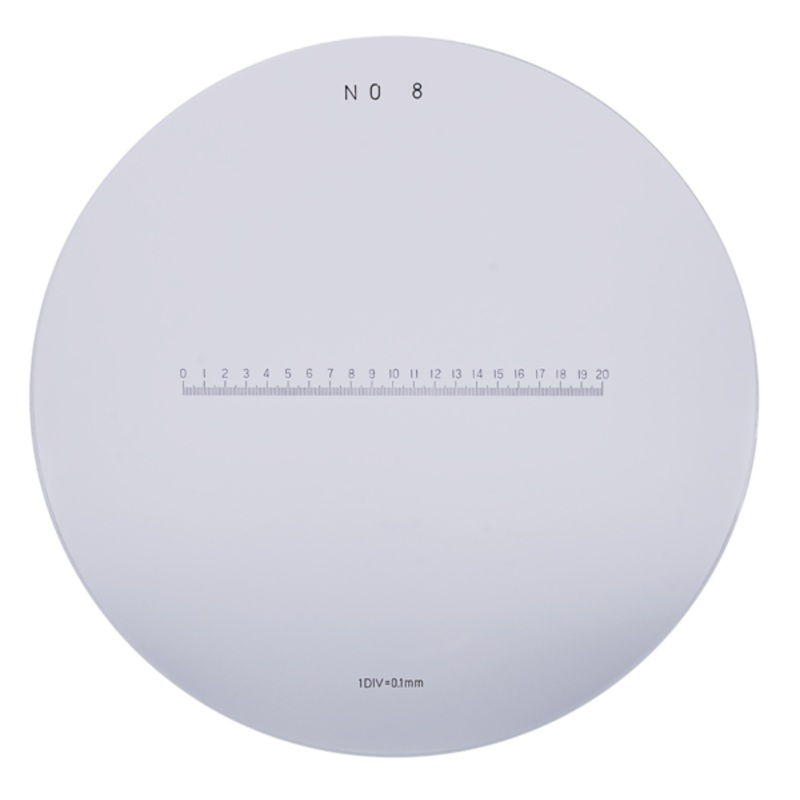

Telecentric, single optical magnification

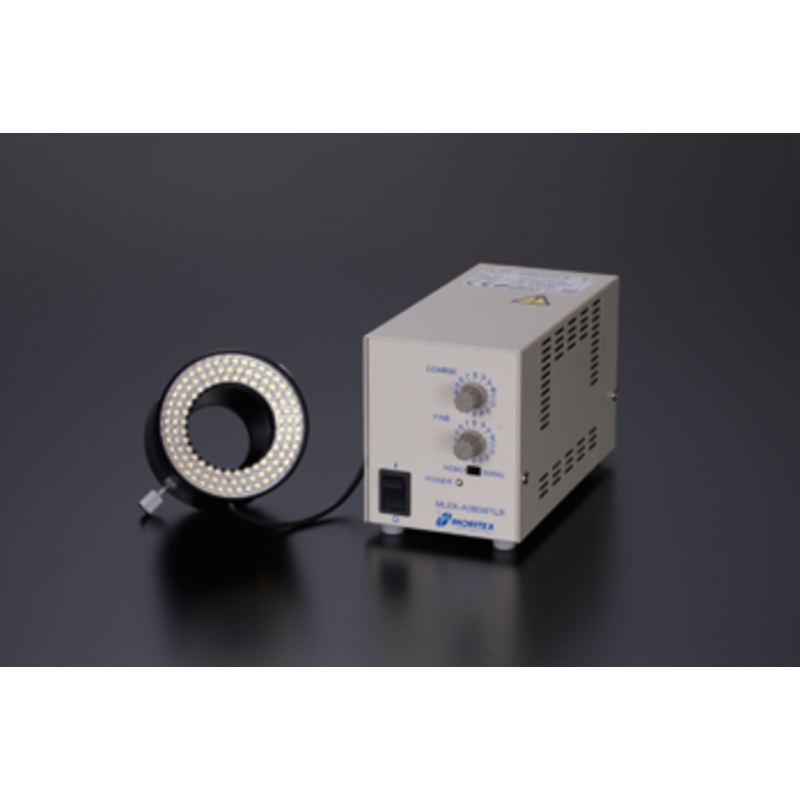

Illumination

Substage LED profile, coaxial LED surface, and programmable 8-sector LED oblique ring light

Metrology Camera

High density megapixel metrology camera

Field of View

62 mm x 46 mm

Max Digital Zoom

15.5 mm x 11.5 mm

Depth of Field

20 mm

Working Distance

115 mm

Controls

GO button, illumination controls, and toggle switch for Z motion control

Software

Metrology Software: Measure-X Measure and Compare

Metrology Software: ZONE3 Express, Prime, or Pro in lieu of Measure-X Productivity Software: Measure-X Analyze, SmartFit 3D, EVOLVE Suite (Design, EVOLVE SPC, Manufacturing, SmartProfile)

Offline Software: Measure-X or ZONE3

System Controller

Windows based, with up-to-date processor and networking/communication ports

Controller Options

24 flat panel LCD monitor, or dual 24 flat panel LCD monitors, keyboard, 3-button mouse (or user supplied)

Power Requirements

100-120 VAC or 200-240 VAC, 50/60 Hz, 1 phase, 400 W

Safe Operating Environment

15-30 C, non-condensing

Rated Environment

Temperature 18-22 C, stable to 1 C, max rate of change 1 C / hour, max vertical gradient of 1 C / meter; 30-80% humidity; vibration <0.001g below 15 Hz

XY FOV Accuracy (E2)

(4.0 + L/50) m

![Kern Sound Level Meter SW 1000 Measuring range Sound 20 dB 134 dB Readability sound [d] (dB)0,1 dB](https://www.micrometerx.com/wp-content/uploads/2025/8/1756621643/kern-sound-level-meter-sw-1000-measuring-range-sound-20-db-134-db-readability-sound-d-db-0-1-db.webp)