Description

3D-Alignment and Positioning Indicator

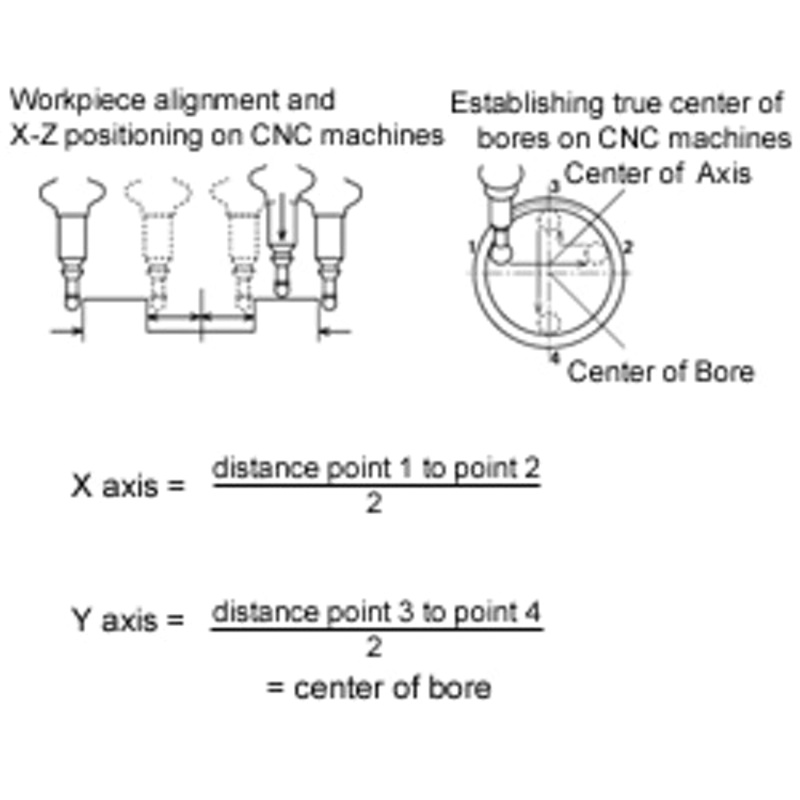

- Advanced concept in finding zero, the true starting point of all 3 axis (X-Y-Z) on workpieces.

-

Probe actually gets deflected in any of the 3 axes until indicator reaches centerline. At this point

the workface (edge) is in a direct true line with the spindle. - Ideal to inspect workpieces in the CNC machine prior to removal.

- Radial run-out compensation! Two adjustment screws in the X and Y axis to align center of the stylus to the center of the spindle axis.

-

With the 3D Taster centered in a toolholder, the workpiece edge can be positively picked up in

one approach, no guessing as with electronic edgefinders. - Conveniently used on conductive as well as non-conductive workpieces.

- Contact point is electrically insulated for safe applications on all CNC Centers and EDM machines.

-

Replaceable stylus with predetermined breakpoint prevents damage in case of accidental overrun.

Overrun protection in all 3 axis. - Operates in vertical and horizontal position.

- Graduation reference lines 0,01 mm (.0004″).

- Accuracy in any direction 0,01 mm (.0004″).

- Standard stylus 41 mm long with 4 mm dia. ball included, short and long styli optional.

- Dial diameter 2″, body length including standard stylus 4-7/8″.

- 3/4″ dia. hardened and precision ground shank.